Geometric Dimensioning and Tolerancing (GD&T) is a symbolic language used on engineering drawings to accurately define the allowable variations in the form, size, and location of features on a part.

It’s a critical skill for engineers and manufacturers, ensuring parts fit together correctly and function as intended.

By mastering GD&T, you can improve product quality, reduce manufacturing costs, and ensure interchangeability of parts.

With a growing demand for professionals proficient in GD&T, finding the right course to guide you through its complexities can be a challenge.

You’re likely looking for a course that provides a solid foundation in the fundamentals, offers practical examples, and helps you confidently apply GD&T principles to real-world scenarios.

After careful consideration of various options, we believe the Geometric Dimensioning and Tolerancing (GD&T) : Basics course on Udemy stands out as the best overall choice.

This comprehensive course provides a strong foundation in GD&T principles, covering everything from basic concepts to advanced applications.

Its clear explanations, practical examples, and engaging exercises make it a great choice for both beginners and those seeking to refresh their knowledge.

However, the ideal course for you depends on your specific needs and learning style.

We’ve reviewed several other excellent GD&T courses on Udemy, each offering unique advantages.

So, keep reading to explore our detailed breakdown of the top contenders and find the perfect course to launch your GD&T journey.

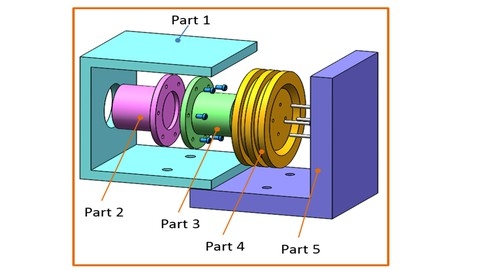

Geometric Dimensioning and Tolerancing (GD&T) : Basics

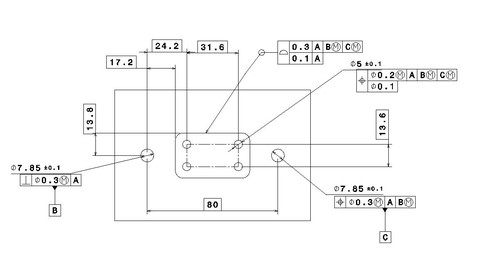

You’ll begin by mastering the fundamentals of engineering drawings, delving into orthographic projections, tolerance concepts, and the significance of fits in mechanical assemblies.

The course seamlessly transitions into the core principles of GD&T, introducing you to essential concepts like feature control frames, datum reference frames, and tolerance zones.

You’ll gain a firm grasp of critical entities like MMC and LMC, understanding how they control part variations and ensure successful assembly.

The course comprehensively covers various geometric controls, including form control (straightness, flatness, circularity, cylindricity), orientation control (angularity, perpendicularity, parallelism), and location control (position, concentricity, symmetry, runout).

You’ll also explore profile control, learning how to define the shape of lines and surfaces accurately.

The course highlights the power of datum shift, a powerful tool for achieving design intent by modifying the datum reference frame.

Furthermore, you’ll engage in practical exercises and real-world examples, applying your newfound GD&T knowledge to interpret engineering drawings and create your own GD&T schemes.

Geometric Dimensioning & Tolerancing : Advanced concepts

This “Geometric Dimensioning & Tolerancing: Advanced Concepts” course takes a deep dive into the intricacies of GD&T, building upon your existing knowledge.

You’ll revisit the fundamentals, ensuring a solid foundation before delving into more advanced concepts.

The syllabus expertly navigates the complexities of profile tolerance, emphasizing its application in both 2D and 3D contexts.

You’ll learn to interpret profile tolerance interpretations and see how it can replace traditional position and orientation controls, making your designs more efficient.

The course then explores the crucial concept of patterns, examining both rectangular and circular patterns.

You’ll master the art of verifying position control with MMC modifiers, developing the ability to analyze and verify parts using GD&T drawings.

You’ll dive into the world of datums, understanding the role of inclined and auxiliary datums in defining and controlling your designs.

The syllabus provides practical examples and quizzes to reinforce your understanding, ensuring you can confidently apply these concepts in real-world scenarios.

Simultaneous requirements are a critical focus, showcasing their impact on gauging and design.

You’ll understand how to implement them in complex assemblies, developing a deeper understanding of their role in GD&T.

The course then takes you into the realm of composite position control, revealing how it can be used to manage multiple features.

You’ll gain a strong grasp of the differences between composite and multi-segment control, visualizing tolerance zones in 3D and becoming adept at verification.

You’ll also learn how to use composite profile control, along with slot control, and explore multiple datum features.

The syllabus introduces the crucial concept of zero MMC, providing examples that showcase its practical applications.

The course introduces the powerful tool of datum targets, highlighting the 3-2-1 principle and demonstrating how datum targets are used in real-world designs.

Finally, you’ll learn how to apply projected tolerance zones, floating fasteners, and fixed fasteners, acquiring the knowledge needed to create designs with complex interrelationships.

The inclusion of exercises and quizzes throughout ensures that you can apply your learning and gauge your progress, ultimately transforming you into a GD&T expert.

Basics of Tolerance Stack-up Analysis and Fits with GD&T

This course is a solid foundation for anyone looking to grasp the fundamentals of tolerance stack-up analysis and geometric dimensioning and tolerancing (GD&T).

You’ll start by understanding the essential concepts of tolerance, accuracy, and precision, and how they relate to different manufacturing processes.

You’ll explore the various factors influencing tolerances, such as material variations and manufacturing methods, and learn how to represent and convert tolerances effectively.

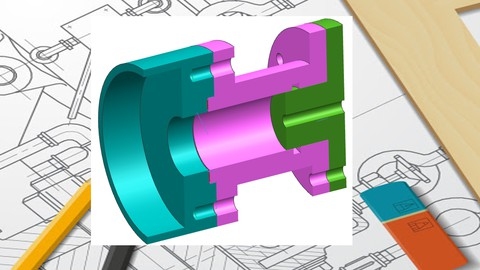

The course delves into the world of “fits,” explaining how they define the relationship between mating parts.

You’ll learn to distinguish between different types of fits, like clearance, interference, and transition fits, and how to decode fit specifications using standard nomenclature.

You’ll also grasp the significance of shaft and hole basis in determining tolerances.

The true value of this course lies in its in-depth exploration of tolerance stack-up analysis, a crucial step in ensuring successful part assembly and functionality.

You’ll analyze real-world examples, such as the gap between car body panels, and discover how techniques like worst-case analysis and statistical tolerancing help account for manufacturing variations.

Furthermore, the course effectively integrates the power of GD&T, showcasing how its symbols define tolerances and control part geometry.

You’ll work through specific examples demonstrating the practical application of GD&T principles.

The course also sheds light on the advantages of statistical tolerancing over worst-case analysis, and equips you with methods for determining the capability of your manufacturing processes using process capability indices.

Tolerance Stack-up Analysis of GD&T-From Beginners to Stars

You’ll embark on a journey that starts with the foundational principles of linear tolerance stack-up, where you learn to calculate the accumulation of tolerances in basic assemblies.

The course quickly progresses to more complex topics like geometric tolerance stack-up, introducing you to the intricacies of applying different types of tolerances, such as profile, position, and runout, in real-world engineering applications.

These concepts are brought to life through numerous case studies, each one carefully crafted to solidify your understanding and provide you with a glimpse into the practical applications of tolerance stack-up analysis.

A key element of the course is its focus on datum features, highlighting their crucial role in tolerance stack-up.

You’ll learn to properly define datum features and understand how their orientation and form can significantly influence the overall tolerance of a part.

The curriculum also delves into more advanced topics like MMC/LMC modifiers, pattern tolerance stack-up, and statistical tolerance stack-up, ensuring you gain a well-rounded understanding of the subject.

A comprehensive case study acts as the capstone to the course, integrating all the concepts you’ve learned into a real-world scenario.

This hands-on experience will solidify your knowledge and equip you to confidently analyze tolerance stack-up in any assembly.

You’ll emerge from this course with the expertise to confidently tackle the challenges of complex designs and avoid the costly mistakes that can arise from improper tolerance control.

GD&T + ISO GPS Full Learning Bootcamp - From Rookies To Star

This course starts with the fundamentals of GD&T and ISO GPS, covering essential topics like datum selection and interpreting feature control frames.

You’ll learn about the different tolerance zones and how they define the allowable variation for features, including the TED, or Total Element Deviation.

The course delves into various tolerance types, such as linear, profile, position, and form tolerances.

Each type has its purpose, and you’ll learn to choose the right one for your design.

You’ll also get hands-on practice using MMC and LMC modifiers, which influence the size of the tolerance zone, crucial for ensuring proper part fit even with manufacturing variations.

The course progresses to datum systems, explaining how they create a reference frame for tolerances.

You’ll learn to specify datum references correctly and understand their impact on feature tolerances.

Beyond the basics, you’ll delve into advanced concepts like orientation tolerances (parallelism, perpendicularity, angularity) and position tolerances (coaxiality, concentricity, symmetry).

These concepts can be complex, but the course effectively breaks them down into digestible pieces, making them accessible.

You’ll also explore runout tolerances, essential for ensuring proper function of rotating features.

The course wraps up with profile tolerances, which define allowable shape variations for features.

You’ll learn to specify these tolerances accurately and understand how they impact part design.

This bootcamp equips you with a comprehensive understanding of GD&T and ISO GPS, both theoretically and practically.

You’ll gain confidence in applying this knowledge to real-world designs, ensuring your parts meet all required specifications.

Beyond the core content, bonus videos focus on practical application.

These videos demonstrate how to use MMC or LMC modifiers effectively based on specific functions, taking your learning to the next level.

They provide real-world examples and deepen your understanding of how to apply your knowledge in practical settings.

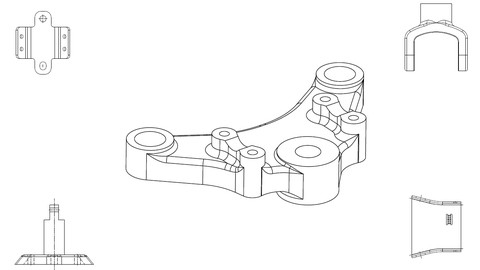

GD&T applied to components with case studies

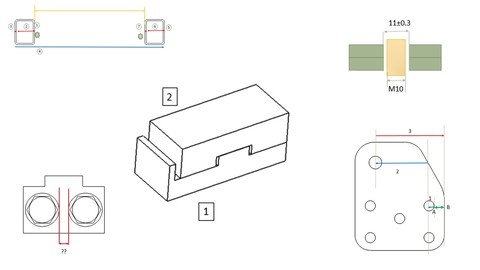

You’ll learn by doing, applying GD&T principles to real-world components, such as a yoke and a punching mechanism.

The course doesn’t just present the theory, it immerses you in the practical application.

For example, the yoke case study dives deep into the design process, showing you how to use GD&T to specify the size, shape, and location of the yoke’s features.

You’ll learn to create detailed drawings and inspection gauges, bringing the theory to life and building your confidence.

The course excels in its case study approach, featuring thirteen diverse components like a slide bracket, a tube bracket, and a rotatable mount.

Each case study presents a unique set of challenges, giving you the opportunity to tackle a wide range of GD&T applications.

The course’s focus on practical components, like a hinge bracket, a special latch, and a check valve, ensures you’ll gain a strong understanding of how GD&T is used in manufacturing.

You’ll learn to communicate your design intent clearly and precisely, ensuring your components meet the required standards.

You’ll understand the intricacies of tolerances, datum features, and feature control frames, enabling you to create robust and reliable designs.

Geometric Dimensioning and Tolerancing (GD&T) Mastery

You’ll start by understanding the importance of GD&T and its role in creating precision in manufacturing.

The course then delves into the core elements of GD&T, covering symbols, notations, and special conditions, equipping you with the foundational knowledge to navigate its complex language.

The course then shifts its focus to the critical area of positional tolerances.

You’ll explore different techniques, like coaxial position tolerances, and discover how to use GD&T to ensure features are precisely located within a design.

You’ll also learn about the specific conditions that apply to positional tolerances, allowing you to fine-tune your designs with greater accuracy.

Next, you’ll explore the nuances of form and size tolerances.

The course helps you understand the different types of form tolerances, teaching you how to control the shape and dimensions of your parts using GD&T.

The section on runout and profile tolerances is particularly valuable, helping you develop a strong understanding of how these tolerances are used to ensure parts have the correct shape and orientation.

Finally, the course dives into the world of datums, the cornerstone of GD&T.

You’ll gain an in-depth understanding of how datums are used to create datum systems, ensuring that parts fit together perfectly.

Basics of GD & T (Geometric Dimensioning and Tolerancing)

This course is a thorough introduction to GD&T, covering a wide range of concepts essential for anyone involved in manufacturing.

You’ll start by understanding the fundamentals of GD&T, exploring its importance and how it ensures precise part fit.

The course delves into the concept of tolerances, explaining the various types and how they are used to define acceptable variations in part dimensions.

You’ll learn about Datum Reference Frames (DRF) and how they serve as the foundation for defining part locations.

The course introduces the ASME Y14.5 standard, highlighting the differences between the 2009 and 2018 versions, providing you with a clear understanding of current industry practices.

The syllabus covers Feature Control Frames (FCF) and their crucial role in communicating precise part requirements.

You’ll explore different control methods, such as Level 1 to Level 4 Control, which dictate the accuracy and precision of parts.

The course doesn’t just present theoretical concepts; it utilizes real-world examples to illustrate practical applications of GD&T in manufacturing.

You’ll also delve into specific tolerances like runout, profile, and symmetry tolerances, learning how to combine FCFs to achieve complex dimensional control.