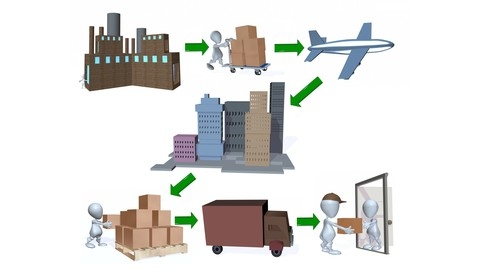

Supply chain management is the backbone of modern commerce, encompassing the intricate network of processes involved in producing and distributing goods, from sourcing raw materials to delivering finished products to consumers.

By understanding the principles of supply chain management, you can optimize efficiency, reduce costs, and enhance customer satisfaction.

Whether you’re aspiring to a career in logistics, operations, or simply seeking to broaden your business acumen, a solid grasp of supply chain fundamentals is essential.

Finding a top-notch supply chain course on Udemy can be a challenge, given the vast array of options available.

You’re searching for a course that not only covers the theoretical foundations but also provides practical insights and real-world applications.

You want a course that’s engaging, comprehensive, and taught by experienced professionals who can guide you through the complexities of this dynamic field.

After careful consideration, we’ve identified Supply Chain Fundamentals: Understanding the Basics as the best course overall on Udemy for grasping the fundamentals of supply chain management.

This comprehensive course provides a solid foundation in key concepts, covering topics such as demand forecasting, inventory management, and production planning.

With clear explanations, practical examples, and engaging exercises, this course is an excellent starting point for anyone looking to delve into the world of supply chain management.

While this is our top recommendation, there are many other excellent supply chain courses on Udemy tailored to specific interests and skill levels.

Keep reading to discover more options that might be the perfect fit for your learning journey.

Supply Chain Fundamentals: Understanding the Basics

This course guides you through the core ideas of supply chains, from the basics of supply and demand to the complexities of manufacturing and inventory management.

You will discover how to anticipate future demand using forecasting methods like the simple moving average and exponential smoothing.

You’ll also learn to calculate forecast error and understand its impact on your supply chain.

You will then explore the world of manufacturing, learning how to select the optimal manufacturing environment, navigate the product life cycle, and design efficient layouts.

The course delves into Sales & Operations Planning (S&OP), teaching you how to craft effective production plans and manage resources using techniques like Resource Requirements Planning (RRP).

You’ll gain mastery over Master Scheduling, learning to create a Master Production Schedule (MPS) and utilize concepts like Rough Cut Capacity Planning (RCCP) and Available-to-Promise (ATP) to manage capacity effectively.

The course then unveils the intricacies of Material Requirements Planning (MRP), guiding you through the Bill of Material (BOM), MRP offsetting and exploding, and the significance of time phasing.

You will also delve into capacity planning, learning how to determine available capacity based on factors like time and utilization.

You’ll then explore production activity control, understanding the critical role of shop order release in efficient operations.

The course then shifts focus to inventory management, emphasizing the importance of customer service, safety stock, carrying costs, and ordering costs.

You’ll explore the Economic Order Quantity (EOQ) and learn to apply techniques like ABC analysis for efficient inventory control.

Finally, you will discover the importance of sustainability in supply chains, learning about the 4R’s and how to integrate sustainable practices into your operations.

You’ll explore Sustainability KPIs and understand how innovation drives sustainable supply chain management.

Fundamentals of Logistics, Supply Chain & Customer Service

This course guides you from the essentials of logistics to the complexities of supply chains and the importance of top-notch customer service.

You will start by grasping the core of logistics and its impact on businesses.

You’ll explore the ins and outs of managing the flow of goods, both inbound and outbound, including the strategic handling of returns through reverse logistics.

You’ll learn how to make smart decisions about storage and distribution, ensuring that goods are in the right place at the right time.

The course then delves into supply chain management, giving you a solid understanding of its goals and how they impact a business’s success.

You will learn how to manage inventory effectively, strategize purchasing, and cultivate strong relationships with suppliers.

You will also explore various facets of manufacturing and operations, including making informed decisions about location, understanding the implications of outsourcing, and recognizing the vital role logistics plays throughout the supply chain.

Finally, you will explore the world of customer service, a crucial element of any thriving business.

You will discover the importance of a well-defined customer service strategy, learning how to set realistic customer expectations and avoid common pitfalls.

This course illuminates the characteristics of highly effective customer service and emphasizes the significance of equipping your team with the right skills.

You will learn how to leverage technology and innovation to elevate your customer service and keep your strategies current in a constantly evolving market.

Logistics and Supply Chains - Fundamentals,Design,Operations

This course equips you with the skills to master the intricate world of logistics and supply chains.

You begin with the fundamentals, exploring concepts and definitions related to supply chain management and logistics, gaining a firm understanding of their structure and functionality.

You then transition into the strategic domain, discovering how to develop and execute effective strategies for both logistics and the supply chain as a whole.

This includes aligning organizational goals with supply chain objectives and understanding the strategic focus and necessary infrastructure.

The course then delves into the practical aspects of supply chain management.

You learn how to master demand management, utilizing forecasting techniques, managing sales and operations planning, and navigating diverse demand environments.

You delve into Material Requirements Planning (MRP) and Distribution Requirements Planning (DRP), developing the ability to efficiently plan and oversee the flow of materials.

The course guides you through capacity management, teaching you to strategically plan and modify capacity to meet fluctuating demand.

You learn to recognize and address customer needs, building strong relationships through Customer Relationship Management (CRM).

You discover how to utilize CRM tools, marketing strategies, and top-tier customer service to foster enduring customer loyalty.

The course emphasizes the critical roles of procurement and inventory management in achieving supply chain success.

You learn to navigate the complexities of the make-or-buy decision, master supplier selection, understand the concept of economic order quantity, and grasp the crucial role of inventory management in minimizing costs and maximizing efficiency.

Supply Chain Essentials: Understanding Planning & Scheduling

This course gives you a deep understanding of supply chain management, focusing on planning and scheduling.

You’ll begin by learning about the Master Planning Hierarchy, which acts as a guide for making smart decisions about your resources.

You’ll explore demand management and discover effective techniques for predicting customer needs and aligning production to meet those demands.

You will then dive into master scheduling, where you’ll master the art of creating a precise production timeline.

This involves understanding capacity planning and ensuring you possess the necessary resources to meet production goals.

Through various forecasting techniques, you’ll learn to anticipate future demand and effectively utilize those forecasts across different stages of your supply chain.

The course then delves into the crucial realm of detailed scheduling and planning, focusing on developing detailed production schedules and expertly managing inventory levels.

You’ll learn how to classify inventory, measure its value, and utilize lot sizing techniques for optimized production.

You’ll discover how to gather and analyze data inputs like inventory status and usage data, becoming proficient in material planning.

Through the course, you’ll become familiar with Material Requirements Planning (MRP), a system that automates material requirement calculations for production.

You’ll also delve into Capacity Requirements Planning (CRP), a tool that ensures you have sufficient capacity to meet your production targets.

Finally, you’ll master the art of Supplier Relationship Management (SRM), learning how to build mutually beneficial relationships with suppliers.

You’ll gain insights into assessing financial health and selecting the right suppliers to optimize your supply chain.

Inventory Management A-Z: Supply Chain & Business Operations

This course guides you through the complexities of inventory management, starting with the fundamentals.

You’ll understand what inventory is, its various types, and its significance in the business world.

You’ll also discover the financial and operational costs associated with inventory, including the impact of insufficient stock levels.

The course then introduces you to essential metrics for measuring inventory performance, such as Inventory Turns, Days on Hand, and GMROI.

You’ll explore the ABC Analysis, a technique for classifying inventory based on value and usage, and learn how to use tools like Little’s Law to optimize your supply chain.

The course emphasizes understanding the “why” behind inventory management decisions, equipping you with the knowledge to analyze data effectively.

You’ll delve into inventory dynamics, mastering concepts like Economic Order Quantity (EOQ) and Economic Batch Quantity (EBQ) to determine optimal order sizes and timing.

The course explains the importance of safety stock and teaches you how to calculate it using statistical methods like standard deviations and normal distributions.

Practical examples, like the Scottish Whiskey case study, illustrate these concepts, making them easy to grasp and apply.

Supply Chain: Demand Planning (Sales Forecasting and S&OP)

You’ll learn all about demand management and how to build unconstrained demand forecasts.

The course covers the key difference between demand and forecasts, giving you a solid foundation.

One of the standout features is the in-depth coverage of sales forecasting techniques.

You’ll dive into regression analysis, including hands-on exercises to solidify your understanding.

The course also explores exponential smoothing, another essential forecasting method, with practical exercises to apply what you’ve learned.

But it’s not just about the techniques – you’ll also learn how to integrate supply and demand planning, strike the right balance between different forecasts, and understand the importance of rolling forecasts.

The course even includes exercises on calculating forecast accuracy and understanding the significance of different accuracy measures.

Time fence policies, a crucial aspect of demand planning, are covered as well, along with exercises to reinforce the concepts.

And if you ever miss a sales forecast, the course has you covered with strategies to handle that situation.

With a focus on practical exercises and real-world examples, you’ll gain the skills to become a forecasting pro.

Supply Chain: Inventory Control & Safety Stock Calculation

This course teaches you how to calculate safety stock, which is the extra inventory you keep to avoid running out of products.

You will learn different formulas used to calculate safety stock, factoring in things like how long it takes to get new products and how much customer demand changes.

You’ll discover various types of safety stock, such as the stock needed for sudden increases in demand or delays in the supply chain.

You will explore practical techniques to manage your inventory efficiently.

You’ll learn to tell the difference between items that are part of your inventory and those that aren’t.

You’ll also learn how to control the costs of keeping inventory, like storage and insurance.

The course uses the Pareto Principle, which states that 80% of your results come from 20% of your efforts.

This principle helps you focus on the most important items in your inventory.

You will also discover different ways to reduce the amount of safety stock you need.

This includes making your demand forecasts more accurate, improving your transportation systems, and forming strong partnerships with your suppliers.

You’ll learn about different strategies, like the “Make to Stock” and “Make to Order” approaches, and understand how they impact your safety stock needs.

You’ll even discover advanced techniques like cross-docking, which minimizes the need for warehouses.

Warehouse Management in Logistics & Supply Chain Management

If you’re looking to master the ins and outs of warehouse operations, this course on warehouse management within the logistics and supply chain field might be the ticket.

You’ll begin by grasping the importance of warehouses in the grand scheme of supply chains.

You’ll explore different warehouse environments such as public, private, government, and even refrigerated facilities.

You’ll learn the ins and outs of customs procedures and the purpose of bonded warehouses.

The course then dives into the heart of warehousing – its layout and the flow of goods.

Imagine optimizing warehouse space with different storage methods, from basic floor storage and sturdy pushback racks to high-tech radio shuttle racking systems and towering high-bay warehouses.

You’ll become familiar with the machinery that keeps a warehouse humming – gravity conveyors, powered conveyors, and various forklifts – each playing a crucial role in moving goods efficiently.

Prepare to journey through the five key stages of warehouse operations: receiving, putting away, picking, packing, and finally, shipping.

You’ll uncover the nuances of receiving processes and how to fine-tune them for maximum efficiency.

You’ll explore various picking methods used in modern warehouses, including high-tech options like pick-to-light systems, voice-directed picking, and even vision-directed picking.

You’ll also learn about strategic picking approaches such as batch picking, zone picking, and wave picking.

Finally, the course unpacks the essentials of packing, from different packaging types and the art of palletizing to the secure methods of shrink-wrapping and the critical role of product labeling.

Also check our posts on: