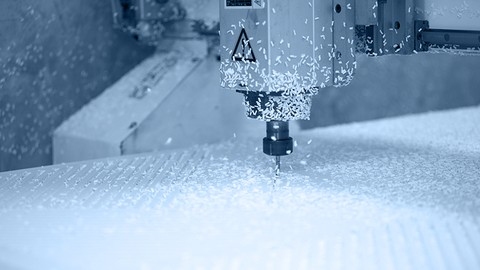

Computer Numerical Control (CNC) machining is a cornerstone of modern manufacturing, enabling the precise and automated creation of parts from various materials.

From aerospace components to intricate medical devices, CNC machining plays a vital role in bringing designs to life.

By learning CNC programming, you gain the power to control these sophisticated machines, opening doors to exciting careers in manufacturing, engineering, and design.

You’ll be able to translate digital designs into physical realities, shaping the world around you with precision and efficiency.

However, finding the right CNC course on Udemy can feel like navigating a complex maze of options.

With countless courses vying for your attention, it’s easy to feel overwhelmed and unsure where to begin.

You’re seeking a course that not only provides a solid theoretical foundation but also equips you with the practical skills needed to confidently operate CNC machines and create real-world projects.

After careful consideration and review, we’ve determined that the Introduction to CNC Programming course is the best overall option on Udemy.

This course strikes the perfect balance between theory and practice, guiding you through the fundamentals of CNC programming with clear explanations and engaging examples.

You’ll learn about G-code, coordinate systems, and essential machining operations, building a strong foundation for more advanced concepts.

While the Introduction to CNC Programming course stands out as our top pick, Udemy offers a plethora of other excellent CNC courses tailored to specific interests and skill levels.

Whether you’re interested in Fusion 360, Mastercam, or G-code programming, there’s a course out there for you.

So, keep reading to discover more recommendations and find the perfect CNC course to launch your journey into the world of precision machining.

Introduction to CNC Programming

This “Introduction to CNC Programming” course is a solid foundation for anyone looking to get started in the field.

You’ll begin with the fundamentals, learning about the Cartesian coordinate system, G00 and G01 commands, and the concept of cutter compensation.

These concepts are introduced in a practical way, using “Hello World” examples to help you grasp the basics.

You’ll also learn about the importance of units of measurement, tool numbers, spindle speeds, and how to utilize MCODES.

The course takes you through the process of programming a profile, a radius, and teaches you the valuable technique of climb milling.

You’ll explore both absolute and incremental programming, and then put your knowledge to the test with a detailed project called “The Widget.”

This hands-on project guides you through the steps of laying out header information, face milling, machining slots, and programming the profile.

The final project, “The Thingy,” challenges you to further your skills by applying what you’ve learned to a more complex scenario involving profiles and slots.

The instructor goes above and beyond by providing access to bonus information, including a free “Machinists handbook” and links to additional CNC programming courses.

This course is well-structured, provides practical examples, and gives you the necessary tools to become proficient in CNC programming.

Fusion 360 tutorial for CNC machinists

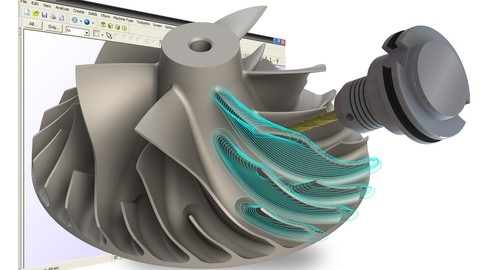

This course is a solid introduction to Fusion 360’s CAD/CAM capabilities, assuming you have some basic familiarity with these concepts.

You’ll dive right into the program, starting with a clear explanation of the menu and navigation, which is essential for navigating its powerful features.

You’ll then move into the core of CAD modeling, mastering techniques like using constraints and dimensions to create accurate parts.

You’ll learn to sketch, create fillets and pockets, and understand how these skills are essential for any CNC machinist.

The course shifts gears to CAM, where you’ll discover how to create precise toolpaths for your CNC machine.

You’ll learn to select the right tooling for different machining tasks like face milling and pocket milling, which directly impacts the quality of your finished parts.

You’ll also explore how to adjust cutting depths, passes, and even output G-Code, the language your CNC machine understands.

One of the course’s strengths lies in its focus on converting DXF files into toolpaths.

You’ll learn how to seamlessly integrate designs from other programs into Fusion 360 for machining, a valuable skill for many professionals.

The course doesn’t stop with the basics.

You’ll also practice creating a lifting eye, a challenging project that demonstrates advanced 3D sketching techniques.

You’ll master adaptive clearing roughing, parallel finishing, and different drilling cycles, all crucial for producing high-quality parts.

Fusion 360 CAD/CAM for CNC routers

This Fusion 360 CAD/CAM for CNC routers course equips you with the skills to design and manufacture parts using this powerful software.

You’ll start by mastering the Fusion 360 interface, navigating its menus and understanding its core functionalities.

You’ll then learn about the crucial concept of constraints, which act like invisible guidelines to ensure your designs are dimensionally accurate and consistent.

From there, you’ll create a basic part, gaining proficiency in sketching and using various design tools.

The course then dives into the world of CAM, allowing you to translate your designs into tool paths that your CNC router can understand and execute.

You’ll learn how to prepare DXF files, a standard format for exchanging designs, for your CNC router.

Throughout the course, you’ll build a “Birthday key” from start to finish, using the skills you’ve learned in sketching, modeling, rough machining, and finishing.

This project will solidify your understanding of the entire process, from design conception to finished product.

You’ll also learn how to perform profile routing and post-process your work, guaranteeing your designs are ready for production.

Basic G-code Programming for CNC Mills.

This course provides a solid foundation in G-code programming for CNC mills, covering essential concepts and practical applications.

You’ll begin by understanding the Cartesian coordinate system, the language CNC machines use to navigate space.

This course then guides you through the G-Wizard Editor, a valuable tool for creating and visualizing G-code programs.

You’ll learn to create tool paths, which are the routes your cutting tool will take, using specific G-code commands for straight lines, arcs, and circles.

The course doesn’t just teach you how to write G-code; it equips you with essential knowledge about work offsets and tool length offset, critical for achieving accurate machining results.

You’ll also gain valuable knowledge of blueprint reading, a skill essential for interpreting design specifications and planning your machining process.

The syllabus dives deep into practical aspects of CNC programming.

You’ll explore various drilling canned cycles, which are pre-programmed sequences for repetitive drilling operations, including G81 for drilling, G83 for peck drilling, and G84 for tapping.

This will help you automate repetitive tasks and increase your efficiency.

The course even introduces you to subroutines and subprograms, which allow you to break down complex operations into smaller, more manageable segments.

This course emphasizes both theoretical understanding and practical application, preparing you for real-world scenarios.

CNC Milling machine programming using G-Code

This CNC Milling machine programming course using G-code offers a comprehensive introduction to the world of computer-aided manufacturing.

You’ll embark on a journey from the very basics of G-code programming, mastering essential concepts like setting datums and defining working planes using G17, G18, and G19 codes.

The course guides you through programming a profile part, providing a practical foundation for more complex tasks.

You’ll dive into the efficient world of canned cycles, learning how to implement G81 drilling, G82 counter boring, G83 peck drilling, and G84 tapping for faster and more accurate machining.

You’ll also gain proficiency in utilizing G85 and G86 boring cycles, essential for creating precise bores within your parts.

The course culminates in a hands-on project involving the programming of a “Doobry” part.

You’ll learn to apply helical spiral milling, G86 boring, and other techniques to create a finished part.

This practical experience will solidify your understanding of the theoretical concepts learned throughout the course.

Mastercam l CNC Programming

If you’re seeking a comprehensive MasterCAM training program, Mastercam l CNC Programming offers a well-structured curriculum that guides you from the fundamentals to advanced machining applications.

You’ll begin by mastering the basics of MasterCAM, learning how to utilize the mouse and create fundamental geometric shapes like lines, circles, and arcs.

This foundation allows you to progress to more intricate designs, such as rectangles, ellipses, and even text, building a strong understanding of the software’s capabilities.

The course then delves into the realm of solid creation and modification.

You’ll discover the power of commands like Extrude, Revolve, and Loft to shape cylinders, spheres, and cones, and learn to manipulate these solids using Boolean operations, chamfering, and filleting.

This level of manipulation allows you to combine shapes, create holes, and even apply draft angles, giving you the ability to create intricate 3D models ready for the CNC machine.

Mastercam l CNC Programming equips you with the essential skills to leverage MasterCAM for a range of machining operations.

You’ll master the creation of toolpaths for milling, drilling, and turning, encompassing techniques like facing, pocketing, contouring, and threading.

You’ll explore different cutting methods, engage in simulation exercises, and learn to configure your machine settings.

This practical knowledge transforms you from a MasterCAM user to a skilled programmer capable of creating complex parts with a CNC machine.

The course culminates with hands-on projects, allowing you to put your acquired skills into practice by creating parts for real-world applications, such as molds and dies.

This immersive experience solidifies your understanding of MasterCAM and equips you with the confidence to program CNC machines and produce high-quality components.

Fusion 360 for CNC - The best guide for beginners

You’ll start by delving into the world of CAM, learning essential vocabulary and understanding G-code, the language of CNC machines.

You’ll then get hands-on, creating your first toolpath for a facing operation, and then progress to more challenging tasks like creating 2D pockets and 3D toolpaths.

Throughout the course, you’ll master crucial skills like defining stock, creating tools, and optimizing feeds and speeds for your projects.

The syllabus dives into various toolpaths, including drilling and contouring operations, and even covers the valuable technique of double-sided machining.

You’ll also learn how to export G-code, the instructions your CNC machine uses, and how to plan tests to ensure your projects run smoothly.

A key strength of this course is its focus on practical application, with sections like “Planning tests and creating toolpaths from 2D drawings” showing you how to translate designs into executable CNC commands.

The inclusion of a bonus “Tool Selection Guide” demonstrates the course’s commitment to equipping you with the knowledge you need to succeed.

Mastercam CAD CAM and CNC Milling Programming

This Mastercam CAD CAM and CNC Milling Programming course offers a solid foundation in the world of CNC machining.

It covers a wide range of topics, from fundamental design concepts to advanced programming techniques.

You’ll gain a thorough understanding of Mastercam 2024 and Solidworks, learning how to create intricate 2D and 3D designs, essential for any CNC machinist.

The course delves deep into the creation of toolpaths, the backbone of any CNC program.

You’ll learn how to generate toolpaths for various operations, including Face Milling, Contour Milling, Pocket Milling, and more.

You’ll also master advanced techniques like Variable Radius Milling and 3D Finish Blend, which enable you to achieve complex geometries and high-quality finishes.

The syllabus effectively progresses from foundational knowledge to complex applications, teaching you how to program CNC machines for various tasks.

You’ll explore the fundamentals of cutting, learn to program for different CNC milling machines, and gain experience in translating designs into GCode, the language CNC machines understand.

The course also introduces you to 3D High Speed Milling, a powerful technique for maximizing efficiency and achieving exceptional surface finishes.

You’ll learn how to optimize your machining processes, reducing cycle times and improving the overall quality of your work.

The final segment delves into Feature Based Modeling (FBM) with C++, empowering you to automate design and machining processes.

You’ll discover how to use C++ to create intricate designs and generate toolpaths for various machining operations, giving you greater control and flexibility over your projects.

This course is a valuable resource for individuals looking to embark on a career in CNC machining or enhance their existing skills.

The comprehensive curriculum and practical approach make it an excellent choice for beginners and seasoned professionals alike.